After spending Sunday morning hanging out at C&C, we felt that it was simply too early to call it a day. We hit the road to Elyson's house a few minutes away and got to leisurely firing off some snaps. There aren't too many opportunities for me to hone my skills during the winter so the empty street was just what I needed.

I wasn't shooting alone as Elyson was giving it a go as well but for me it wasn't just about the practice; having been following Mike's progress step by step via social media and daily iMessage exchanges, it was exciting to finally see it in person and take in all of the little details and intricacies of the build.

One of the things that caught my attention was how the slim NRG quick release has to be spun counterclockwise while pressing the lock button for the wheel to be detached. I was unaware of this since my regular NRG quick release simply detaches via clamping of both handles, though nothing more than a trivial observation that I had made in person.

What really impressed me however was how "right" the car had come together. The front lip and carbon fiber hardtop had been sprayed by Mike and yet you'd never be able to tell because the paint matches the factory Silverstone Silver Metallic seamlessly. There were no clunks or strange noises aside from the natural buzzing and drivetrain noise the S2000s are known for. With the removal of the carpet and sound deadening, the mechanical symphony has simply been heightened.

Evan had worked his magic on the fenders to retain the OEM shape while having ample room on the inside for suspension travel. The alignment was right on the mark too because even at full lock, the front tires don't rub so that says it all about how it came together. The rears are fine also but occasionally rubbed very slightly on big road gaps which isn't a problem especially since it will be receiving a corner weight balance and alignment in a few weeks by none other than Evan, the suspension setup guru.

I'm all about the no frills approach. There wasn't a need for extended studs, hence OEM length ARP studs were chosen for the added strength and safety. Bright yellow PTFE coated professional grade steel lug nuts sit tightly at home while "breaking the mold" from the silver body and wheels.

The trip to C&C was so short that the new brakes and tires hardly got worn in. HP+ pads work well in elevated temperatures but it was too cool of a day to keep any heat in them especially with the APM Racing vented J hook rotors which provide a noticeable cooling advantage. Mike will have to manage that a bit more closely during this early stage of Spring until we begin to see hotter days on the regular.

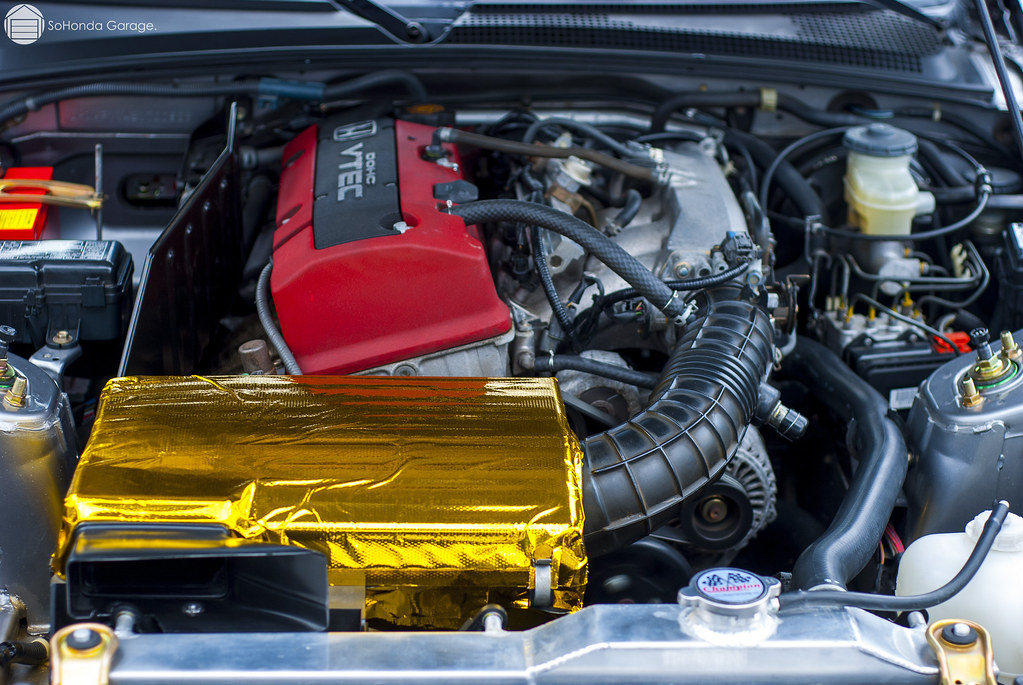

The engine compartment is another area where the function meets the form. Most noticeably at first glance, the factory airbox has been stripped of its resonator and then wrapped in gold heat barrier tape to shelter the cold air coming in from the heat produced by the 2.0ℓ engine sitting behind it.

A batch of brackets and hardware were pooled together and tumbled in a cadmium plating process to give the metals a protection that's durable against the elements in typical SHG fashion.

A new battery was in order and a Buddy Club lightweight dry cell battery fit the bill just right to save a few lbs, tied down with none else than the replated OEM bracket.

Fortune Auto 510 series coilovers were chosen for their excellent customer service, valving quality, pound for pound performance and serviceability for when, and if the setup needs a revalving.

It was during Evan's trackday at Watkins Glen last year that I conjured up the idea to create a series of photographs with all SHG members standing next to their rides. "The Power Of Dreams" series, is a representation of one's ability to accomplish what they set out to do when they put forth their best efforts.

"True happiness lies in the completion of work using your own brains and skills". That is one of Soichiro Honda's most famous quotes and what I want to represent with the series.

I am confident that this is only the beginning of something much bigger as one of SHG's goals as a group is to inspire others to refine their capabilities and become motivated to not only do good work, but great work. When I see the results of a properly executed build such as this one from a planning and budgeting perspective, I realize that no matter which stage one's build is at, that it can always be improved or be further perfected, someway, somehow.

Mike's work reflects that; with inspiration for this build stemming from world class level FIA World Endurance Championship LMGTE class cars, it's no surprise how good the workmanship is. The custom fabbed SHG rollbar sits less than a 1/4'' away from the roof and is a true testament to the quality standards set about even for a first time welder.

Mike always told me: "If there's a will, there's a way". This is what he means, making your dreams come true, from mind to reality.

A trackday at the new Thompson Speedway road course is already in sight this summer so the journey to fine tune the car as a whole begins now. Props to Mike, his supportive wife Lauren and all of the friends involved to getting the car to where it is now. Sincerely, thank you for the inspiration you've given us!

-Claudio